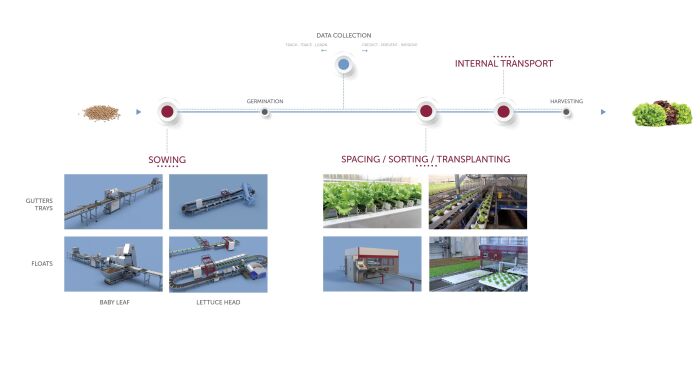

In hydroponic cultivation, continuity, precision, and hygiene are key. Flier Systems provides a fully automated process for growing leafy greens such as lettuce, baby leaf, and other water-based crops, from sowing to harvesting.

Hydroponics/CEA

There is a global demand for food safety, food availability and food security. This calls for predictability in food production with minimal use of water, reducing pesticides and a strong reduction of the nutrients required. With regard to the cultivation choices that are made, various trends can be observed. The fastest-growing in this field is the so-called hydroponics market. Within this hydroponics or Controlled-Environment Agriculture (CEA) market, we can distinguish various cultivation methods, for example, Deep Flow Technique (DFT) and Nutrient Film Technique (NFT). Flier Systems has all necessary machinery available for physical seed/plant handling and works with a variety of partners that supply the cultivation systems.

Sowing

The process starts with precision sowing into gutters, trays, or floats. Depending on the crop (e.g. baby leaf or lettuce heads), we offer dedicated sowing lines tailored to each growing method. Automated filling, sowing, and transport systems ensure each cell or cup is filled uniformly and accurately, laying the foundation for consistent germination.

Germination

After sowing, the trays, gutters, or floats are transferred to germination rooms or climate chambers, where temperature and humidity are tightly controlled. Automated infeed and outfeed systems keep the workflow uninterrupted and labour-efficient.

Spacing / Sorting / Transplanting

During the growth phase, plants are spaced, sorted, or transplanted as needed. With vision technology and robotics, Flier offers solutions for:

Spacing – creating optimal distance between plants

Sorting – selecting based on visual quality or growth stage

Transplanting – relocating plants into new growing systems

This ensures uniformity and optimal use of growing space.

Internal Transport

Our internal transport systems automatically move trays, gutters, or floats through the facility. Labour is reduced, and workflows stay consistent, ideal for high-volume hydroponic cultivation.

Harvesting – in collaboration with partners

While Flier Systems does not manufacture its own harvesting solutions, we collaborate with specialised partners to ensure a seamless connection with our automation systems, resulting in a fully connected solution from seed to harvested crop.