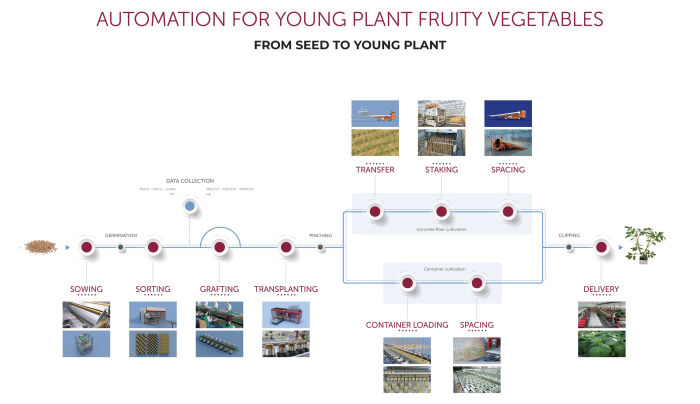

At Flier Systems, we believe in smart automation from the very first moment, the seed, to the delivery of a strong, uniform young plant. Discover below how our automated process helps growers around the world work more efficiently, precisely, and sustainably.

The process

Fruity vegetables (also known as salad) include tomatoes, aubergines, peppers, cucumbers and courgettes. The most commonly used cultivation medium for these crops is stone wool. As a supplier of mechanization for the processing area, Flier Systems offers a wide range of solutions for the cultivation in stone wool. Solutions are available for the entire process, from seed to deliverable plant, contributing to a uniform crop, lower labour costs, and ensuring that the tedious work is minimised.

Sowing

It all starts with a perfectly placed seed. Our sowing solutions are designed for maximum precision: each seed is positioned at the exact right depth and location in (plug)trays or plugs. This careful approach ensures every plant gets an equal start, essential for uniform and vigorous emergence.

Sorting

Once the seeds have germinated, our sorting systems take over. Using vision technology, each young plant is individually analysed for vigour, colour, uniformity, and vitality. The plants are then automatically classified into different quality groups, ensuring that only the strongest and most consistent specimens continue to the next phase of the propagation process. The result: uniform batches and maximum efficiency, fully tailored to the grower’s specific needs.

Grafting

Flier Systems' cutting lines support manual cutting insertion, transplanting, topping, and grafting into trays. By centralising the work, they increase capacity, improve quality, and provide insight into individual performance. Ergonomic workstations ease physical strain and enhance working conditions.

Transplanting

Transplanting young fruity vegetable plants requires a high level of precision, especially in stone wool cultivation. With the Ultimate Stone wool Line, Flier Systems offers a fully automated and integrated process: from sowing to the accurate placement of plants into stone wool blocks. A key element that could be added is the TIS, an innovative machine that uses vision technology to position each young plant with pinpoint accuracy. Smart features such as 90° tilting (for peppers), leaf rotation (for tomatoes), and UV cup disinfection significantly increase the speed, precision, and uniformity of the transplanting process, fully tailored to the needs of today’s growers.

Automation for every cultivation system

Whether a grower works on a concrete floor or with container or gutter systems, Flier Systems offers smart solutions that seamlessly integrate with both approaches. For floor-based cultivation, we provide automation for internal transport, spacing, sorting, and logistical processing, fully tailored to the layout of the greenhouse. For container and gutter systems, we integrate automated container handling and spacing solutions. Always modular, scalable, and customised to the grower’s specific needs.

Washing

Hygiene is essential to prevent disease and crop loss in young plant cultivation. For the thorough cleaning and disinfection of trays, crates, and trolleys, Flier Systems partners with Limex, a specialist in cleaning technology. This collaboration enables us to offer integrated hygiene solutions that seamlessly fit within your greenhouse logistics.

Stay tuned