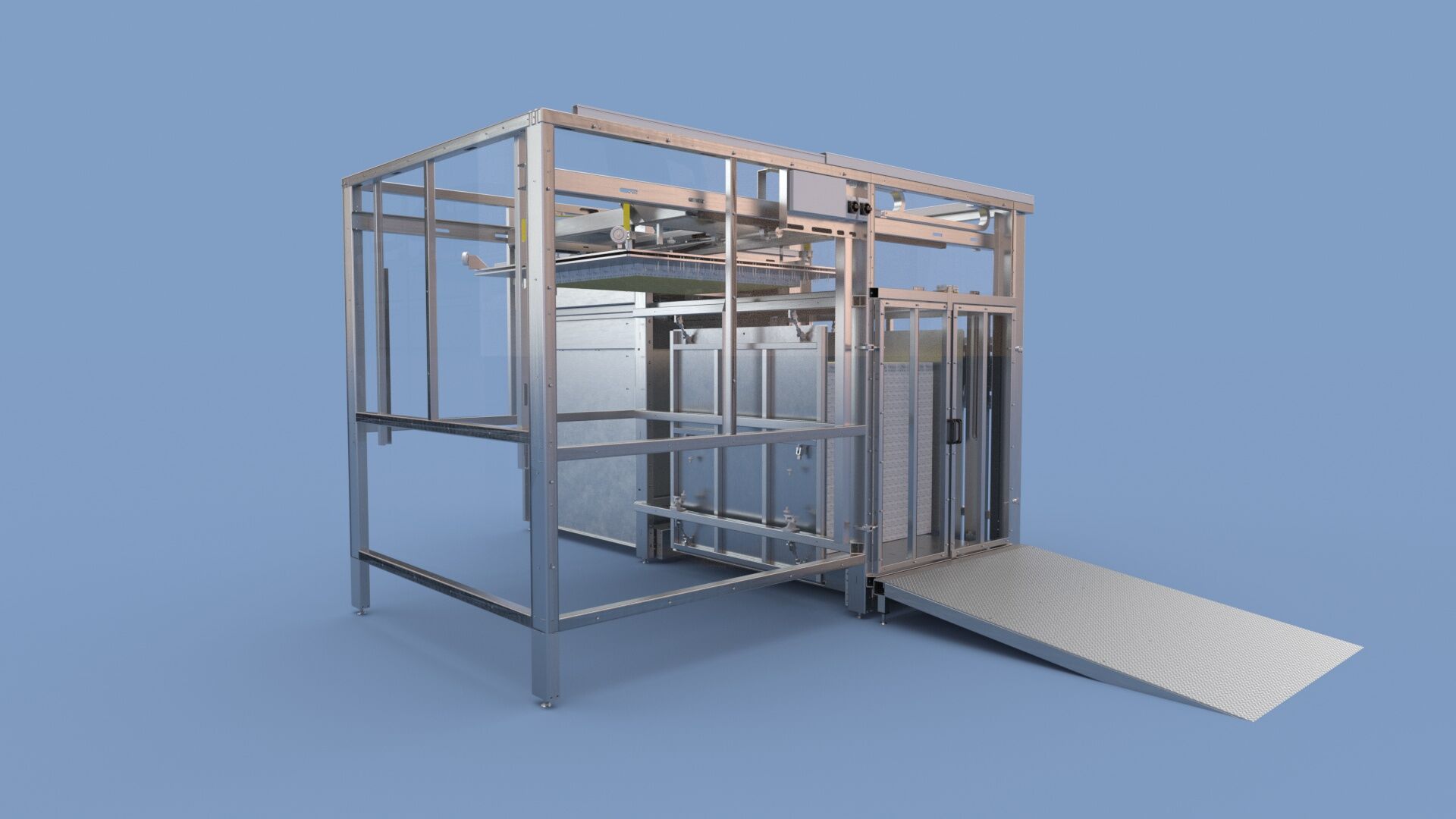

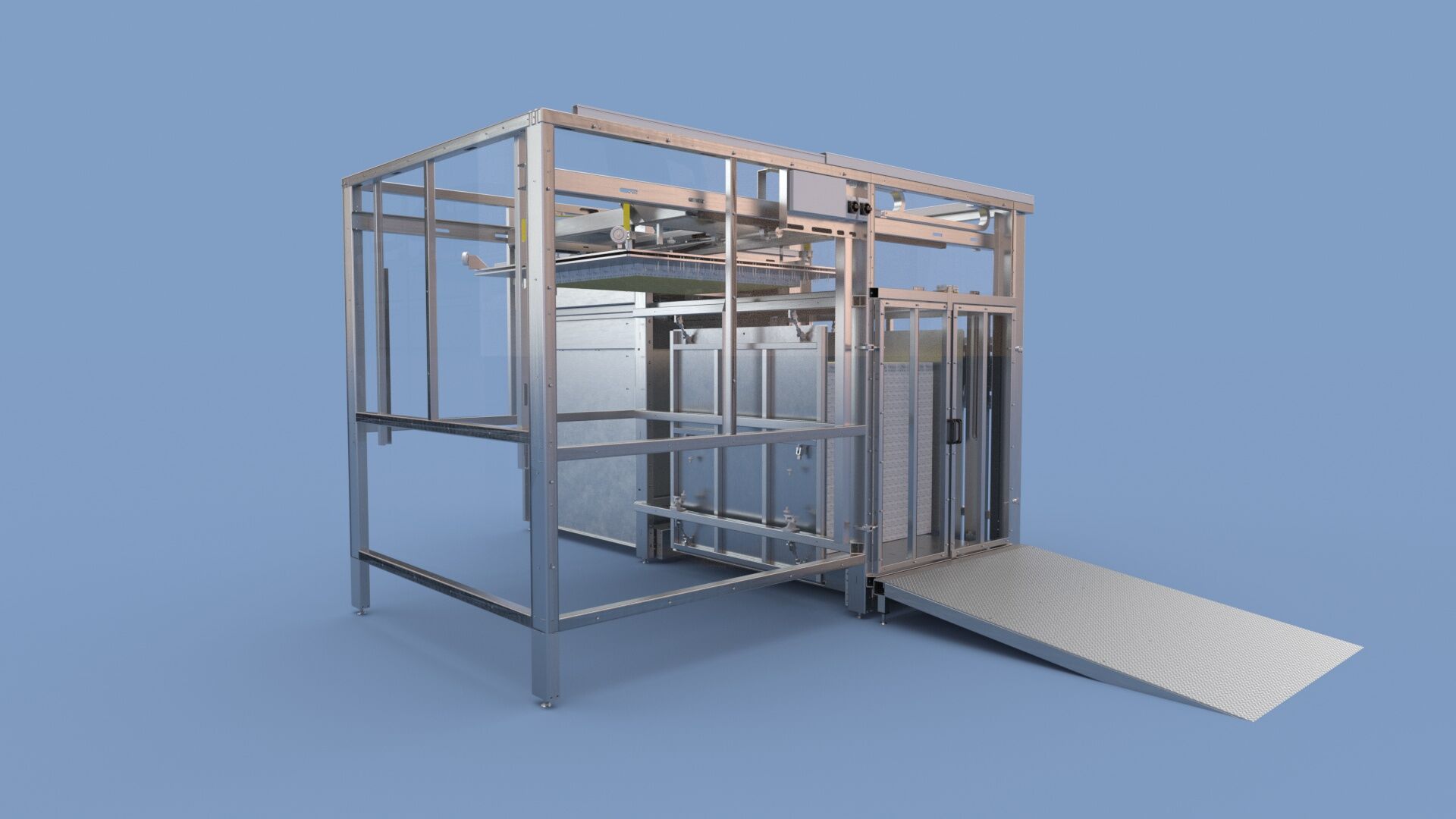

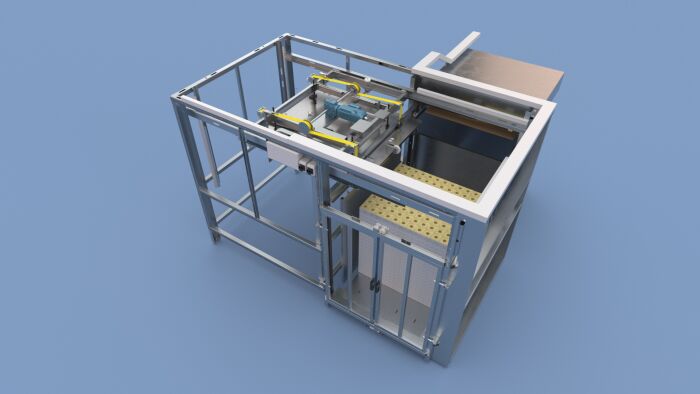

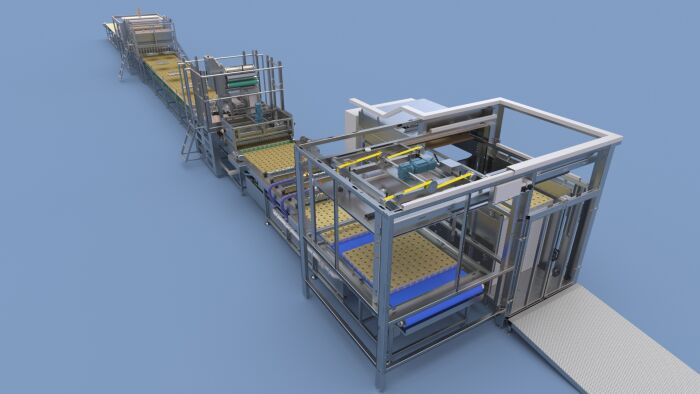

Machine

About the Stone Wool Destacker

The Stone Wool Destacker automates the supply of blocks to the Stone Wool Line. This process includes the removal of the cardboard divider sheets. This allows the Stone Wool Line to keep running uninterrupted.

Benefits

Stay in touch